New battleground for fabs: 2nm technology converges with backside power

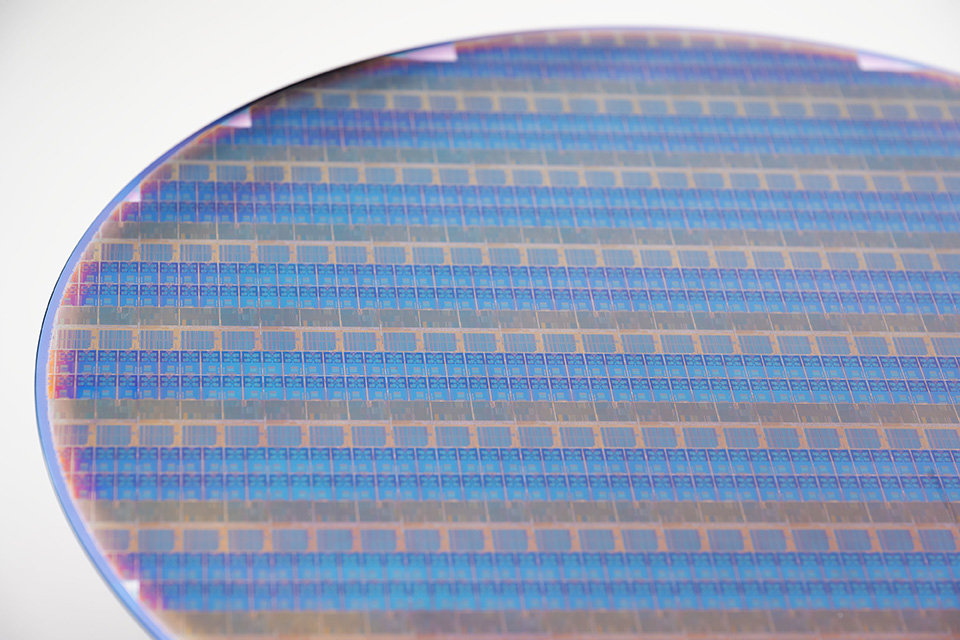

With the continuous breakthrough of semiconductor technology today, the 2nm process has become a new high ground for wafer fab competition. As chip manufacturers around the world deploy this frontier, backside power supply technology (BSPDN) and all-surround gate (GAA) transistor architectures are key to achieving higher performance and lower power consumption.

The 2nm process is not just a reduction in numbers, it represents a qualitative leap forward in semiconductor manufacturing technology. At this process node, up to 300 million transistors per square millimeter of chip area can be integrated, double the current 5nm process, which brings unprecedented improvements in chip performance and energy efficiency.

Intel: Pioneer in backside power technology

Intel's new move into the foundry market is particularly striking. The company plans to put its backside power technology into mass production for the first time at the 20A node, which will start production in the first half of 2024, in tandem with Intel's GAA version, RibbonFET transistors. The introduction of this technology is expected to reduce manufacturing costs while increasing core frequency and cell density.

TSMC: Steady progress in GAAFET technology

In 2025, TSMC plans to begin mass production of N2 nodes based on first-generation GAAFET technology, followed by improved N2P and voltage-enhanced N2X nodes. Despite TSMC's decision to delay the application of backside power technology to the A16 node, its SPR technology is expected to bring significant performance and energy efficiency advantages to HPC products.

Samsung: Comprehensive layout of the improved 2nm process

Samsung has carried out a comprehensive layout on the 2nm process, from SF2 to SF2Z and SF2A, covering multiple fields such as mobile applications, HPC/AI applications and automotive applications. Samsung's SF2Z process will be the first to integrate backside power technology and is expected to reach mass production in 2027.

Challenges and prospects of backside power supply technology

Although backside power supply technology has the potential to improve performance and reduce cost, it still faces challenges in technology maturity, yield, reliability and so on. When weighing the application of this technology, fabs need to consider multiple factors, including heat dissipation, debugging performance, and so on.

Conclusion

The development of the 2nm process is not only a breakthrough in technology, but also a reshaping of the competitive landscape of the global semiconductor industry. With giants like Intel, TSMC, and Samsung moving deeper into this space, we expect to see more innovative technologies emerge to power future smart devices and high-performance computing. At the same time, this will also promote the development of the entire industry towards a more efficient and energy-saving direction, providing solid technical support for global digital transformation.

Recommended Models

● The N76E003AT20 is a Microcontroller IC from Nuvoton that is used in a wide variety of embedded systems and control applications. Including access control system/alarm, temperature sensing equipment, Bluetooth speaker, electric vehicle meter head, digital voltmeter head, gas detector, collector, charger, beauty instrument, small household appliances, etc.

● XC7Z020-2CLG484I is an FPGA chip from XILINX, dual-arm Cortex-A9 MPCore, core processor with CoreSight technology, RAM size of 256 kB, which can be applied to communication systems, industrial automation, video processing, embedded systems.

● The MSP430F5438AIPZR is a 16-bit ultra-low power mixed-signal microcontroller from Texas Instruments for use in a wide range of portable devices, test and measurement, sensing and instrumentation, motor drive and control, consumer electronics, metering, clock and timing.